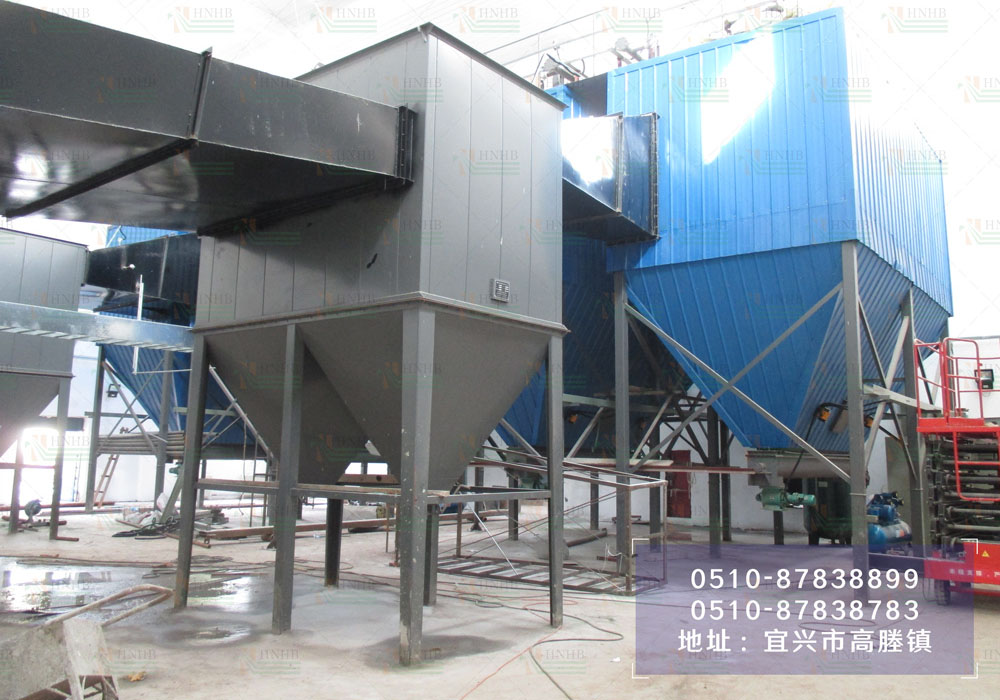

Ceramic multi-tube dust collector

Ceramic multi-tube dust collector is a cyclone type dust collector, suitable for chain furnace, circulating fluidized bed boiler, hot water boiler, biomass boiler, reciprocating furnace, boiling furnace, coal pulverizer furnace, coal water slurry furnace, sintering machine, hot blast stove Industrial boilers and power station boilers of various types and different combustion modes, such as lime kiln and rotary kiln.

First, equipment use and characteristics

1. For other industrial dusts, it can also be treated with this dust collector, such as cement, lime powder and other dust with practical value for recycling.

2. The handling volume is large, the load adaptability is strong, the ceramic movement is smooth and durable, and there is no clogging phenomenon;

3, the small footprint, according to the user's site conditions, according to local conditions, flexible installation, indoors, open air;

4. Export outlets, side outlets, and top outlets to facilitate flue connection;

5, generally no brake parts, easy to manage, simple maintenance, no need to increase any fees;

6. The box body is made of carbon steel, and the non-flange interface is all continuously welded, and the overall air leakage rate is less than 3%;

7. The angle of the lower dust box is designed according to the dust angle of repose, and the angle is generally 55-65° to prevent ash from collecting in the ash bucket;

8. The ash discharge valve adopts manual ash discharge device, and can also adopt electric discharge ash valve with excellent sealing performance.

9. One-time investment is small; compared with electrostatic precipitator, this dust collector has less total investment. Compared with water membrane type dust collector, it does not need circulating water, no secondary pollution, no waste water discharge, no need to increase water treatment equipment. .

220型陶瓷多管除尘器

除尘原理

220型陶瓷多管除尘器采用单支处理烟气量为500m3/h的旋风子,旋风子由导向器、分离筒、排气管组成,均采用优质陶瓷材料制成。

当含尘气体进入除尘器入口,通过陶瓷导向器,于旋风子内部旋转,在离心力的作用下,粉尘和气体分离,粉尘降落在集尘箱内,经卸灰阀排出,并对可以二次利用的粉尘进行回收,净化后气体形成上升气流,经排气管集中至集气室从设备出口排放,达到除尘效果。

技术参数

1、对粒径为3-10μm的粉尘去除效率:85-95%;

2、设备阻力:900-1100Pa;

3、林格曼黑度:0~1级;

290 type ceramic multi-tube dust collector

Dust removal principle

The 290-type ceramic multi-tube dust collector adopts a single-handed cyclone with a smoke volume of 750m3/h. The cyclone consists of a guide, a separation cylinder and an exhaust pipe, all of which are made of high-quality ceramic materials.

When the dust-containing gas enters the inlet of the dust collector, it rotates inside the cyclone through the ceramic guide. Under the action of the centrifugal force, the dust and the gas are separated, and the dust falls in the dust box, and is discharged through the ash discharge valve, and can be discharged twice. The used dust is recovered, and the purified gas forms an ascending airflow, and is discharged to the plenum through the exhaust pipe to discharge from the equipment outlet to achieve the dust removal effect.

Technical Parameters

1. The dust removal efficiency of particle size 5-10 μm: 82-90%;

2. Equipment resistance: 800-1000Pa;

3. Ringermann blackness: 0 to 1 level;

360 type ceramic multi-tube dust collector

Dust removal principle

The 360-type ceramic multi-tube dust collector adopts a single-handed cyclone with a flue gas volume of 1500m3/h. The cyclone is composed of a guide, a separation cylinder and an exhaust pipe, all of which are made of high-quality ceramic materials.

When the dust-containing gas enters the inlet of the dust collector, it rotates inside the cyclone through the ceramic guide. Under the action of the centrifugal force, the dust and the gas are separated, and the dust falls in the dust box, and is discharged through the ash discharge valve, and can be discharged twice. The used dust is recovered, and the purified gas forms an ascending airflow, and is discharged to the plenum through the exhaust pipe to discharge from the equipment outlet to achieve the dust removal effect.

Technical Parameters

1. Dust removal efficiency of particle size above 10 μm: 80-90%;

2. Equipment resistance: 700-900Pa;

3. Ringermann blackness: 0 to 1 level;

480 type ceramic multi-tube dust collector

Ceramic multi-tube dust collector is a cyclone type dust collector, suitable for chain furnace, circulating fluidized bed boiler, hot water boiler, biomass boiler, reciprocating furnace, boiling furnace, coal pulverizer furnace, coal water slurry furnace, sintering machine, hot blast stove Industrial boilers and power station boilers of various types and different combustion modes, such as lime kiln and rotary kiln.

Dust removal principle

The 480-type ceramic multi-tube dust collector adopts a single-handed cyclone with a flue gas volume of 3000m3/h. The cyclone is composed of a guide, a separation cylinder and an exhaust pipe, all of which are made of high-quality ceramic materials.

When the dust-containing gas enters the inlet of the dust collector, it rotates inside the cyclone through the ceramic guide. Under the action of the centrifugal force, the dust and the gas are separated, and the dust falls in the dust box, and is discharged through the ash discharge valve, and can be discharged twice. The used dust is recovered, and the purified gas forms an ascending airflow, and is discharged to the plenum through the exhaust pipe to discharge from the equipment outlet to achieve the dust removal effect.

Technical Parameters

1. Dust removal efficiency of particle size above 10 μm: >95%;

2. Equipment resistance: ~700Pa;

3. Ringermann blackness: 0 to 1 level;

Equipment selection

Calculation of the number of cyclones required inside the dust collector

N=Q/C,

N—the number of cyclones (branch):

Q—the amount of flue gas required for processing (m3/h)

C—the amount of flue gas treated by cyclone single tube, (m3/h/branch)

The size of the cabinet is redesigned according to the on-site security space, transportation conditions and installation conditions, on the premise of meeting the dust removal effect.